Pre-Fabricated Steel Cages: A Cost-Effective Solution for Your Construction Needs

Pre-Fabricated Steel Cages: A Cost-Effective Solution for Your Construction Needs

Blog Article

Mastering Steel Mending: Methods for Superior Construction

Mastering steel fixing is an essential element of construction that straight affects the security and durability of concrete frameworks. By comprehending the ins and outs of exact placement, the appropriate use of devices, and common challenges to stay clear of, specialists can significantly enhance general job end results. Adhering to best safety practices not only safeguards workers however also adds to the integrity of the framework itself. As we discover these methods in greater detail, the effects of understanding this critical skill come to be significantly noticeable, questioning about exactly how these methods can change construction methods.

Comprehending Steel Fixing Essentials

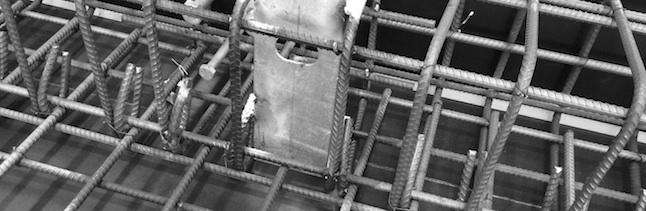

Steel taking care of, a crucial element in the building sector, entails the placement and safeguarding of steel reinforcement bars (rebar) within concrete structures. This procedure is important for making certain the structural integrity and toughness of concrete components, as rebar dramatically enhances tensile toughness, which concrete lacks.

Comprehending the essentials of steel repairing starts with recognizing the numerous sorts of rebar and their requirements, consisting of finishing, grade, and diameter. Rebar is typically made from carbon steel and is offered in different dimensions, which are selected based on the structural requirements of the task.

Additionally, using proper washing sizes and anchorage methods adds to the total stability of the concrete framework. It is necessary for steel fixers to stick to security standards and best methods throughout the installment process, making sure not just the success of the project however additionally the security of all employees involved.

Crucial Devices and Equipment

Successful steel dealing with relies heavily on the right tools and devices to guarantee accuracy and efficiency in the setup process. Secret devices include rebar cutters, which are necessary for making accurate cuts in various sizes of steel bars, and rebar benders that provide the necessary angles for correct placement. In addition, a high quality collection of pliers, particularly tie cord pliers, is crucial for safeguarding rebar with tie wire.

Measuring tools, such as tape actions and laser levels, help with precise design and positioning, while a robust variety of vises and clamps aids in holding the rebar in setting throughout assembly. Safety tools, consisting of safety glasses and gloves, can not be overlooked, as they safeguard employees from prospective dangers related to steel handling.

For bigger jobs, purchasing mechanical devices like rebar linking devices can considerably boost efficiency. Finally, appropriate storage space services, such as racks or bins, assistance arrange products and maintain a secure workplace. By making use of these crucial tools and devices, steel fixers can boost their workflow, ensuring that structural stability and building timelines are met accuracy

Strategies for Accurate Positioning

One effective technique is the use of themes or noting overviews to establish precise locations for steel bars. These guides must be made from long lasting products to stand up to the roughness of construction and must be checked against architectural illustrations to confirm accuracy. Furthermore, utilizing laser levels can greatly boost positioning and elevation precision.

Moreover, maintaining correct spacing between supports is important. This can be attained by using spacers or chairs that are created to hold steel bars in area at the required distance from the formwork.

Regular evaluations during placement must be conducted to ensure compliance with task specs. Any deviations must be dealt with promptly to stop structural weak points.

Finally, cooperation with various other trades is necessary, as clear communication can protect against positioning errors that may develop from conflicting construction activities. By implementing these methods, steel fixers can considerably contribute to the total top quality and safety and security of the building and construction task.

Usual Errors to Avoid

While ensuring the right placement of support steel is important, numerous common mistakes can weaken the integrity of the building process. One constant mistake is inadequate spacing in between steel bars. Not enough spacing can cause blockage, which can endanger concrete flow and bonding, ultimately influencing architectural toughness.

Another common blunder entails overlooking to appropriately protect the reinforcement bars during positioning. Failure to appropriately sustain the steel or connect can result in misalignment, specifically when concrete is put, leading to structural weak points. Furthermore, neglecting the called for cover thickness typically causes premature rust of the steel, decreasing the durability of the framework.

Incorrect cutting and flexing of rebar is one more pitfall that can bring about stress and compression concerns within the concrete. It is important to comply with exact requirements to keep the intended load-bearing capacity.

Last but not least, poor inspection prior to concrete putting can permit these mistakes to go unnoticed. Normal checks and adherence to make specifications are essential to ensure that steel dealing with is done correctly. By staying clear of these typical errors, building specialists can boost the sturdiness and safety of their jobs, guaranteeing an effective end result.

Best Practices for Safety

Guaranteeing the integrity of steel repairing is not just concerning avoiding common blunders however also about applying best see this here practices for safety and security on the building and construction site. An extensive safety and security plan ought to start with correct training and orientation for all employees entailed in steel dealing with. Workers must know with safety and security protocols, devices use, and emergency procedures to mitigate threats effectively.

Keeping you can look here a orderly and tidy workplace is similarly vital. Clear paths and correct storage of products can significantly lower trip and fall dangers. Additionally, carrying out robust interaction protocols, such as hand signals or radios, can protect against accidents triggered by miscommunication.

Lastly, promoting a culture of safety among employee motivates vigilance and accountability. Regular safety and security conferences and seminars regarding potential risks will promote aggressive measures and boost total security on the building site. By adhering to these best practices, the risk of accidents during steel repairing jobs can be substantially decreased.

Conclusion

Mastering steel taking care of is crucial for guaranteeing the architectural honesty and durability of concrete buildings. By using exact methods, utilizing suitable devices, and adhering to finest techniques, the high quality of building can be dramatically boosted.

Grasping steel fixing is an essential element of building and construction that straight affects the security and longevity of concrete structures. By using these necessary devices and devices, steel fixers can improve their operations, making certain that architectural stability and construction timelines are fulfilled with precision.

While making certain the proper placement of support steel is vital, a number of usual blunders can undermine the stability of the building and construction process.Ensuring the integrity of steel dealing with is not just about staying clear of usual blunders however also concerning implementing ideal methods for safety and security on the building and construction site.Grasping steel fixing is vital for making sure the structural honesty and resilience of concrete building and constructions.

Report this page